Before we sell products that perform 25 years in your home, we must be sure they’ll survive . That’s why we employ a unique 5-stage product development process which ensures that no product goes to production until we first push it to its limits of endurance and reliability.

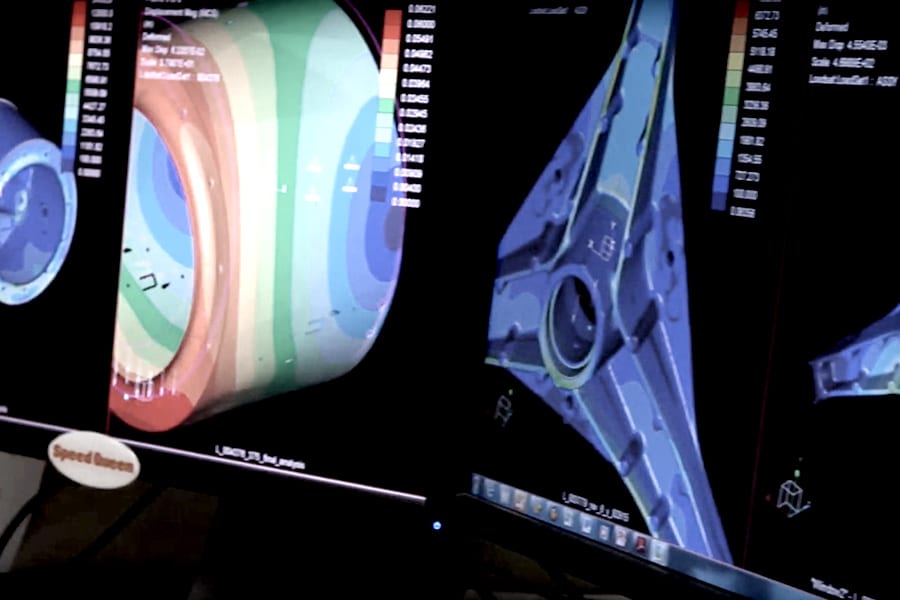

Finite element analysis

Advanced digital engineering and modeling software allows us to optimize the design of every component in order to achieve unprecedented quality levels. We test and calibrate the smallest details before we make something in the physical dimension.

Component testing

Once our products are brought to life in physical form, we subject them to component and subassembly testing that requires each part to perform to at least two times its expected life cycle. This certifies exceptional durability, in even the harshest environments.

Life and load testing

We have the world’s best-equipped laundry equipment test lab. We push our washers and dryers to the breaking point, constantly finding new ways to simulate conditions under which damage might occur over time. That’s why you can be sure that your washing machine and dryer are built to last.

Field testing

Once product performance passes in-house testing, our equipment must show it will perform to commercial-grade standards everywhere, including your home Before products go to full production, we make them work hard in the harshest of real world settings. Our testing gives you true performance and peace of mind.

World-class manufacturing and quality control

Our deep commercial laundry manufacturing experience is evident in every machine. Each is assembled using state-of-the-art technology to ensure our products are consistently built with precision that surpasses our competition, and your expectations.